A robust and flexible warehouse management system (WMS) is necessary in today’s fast-paced and ever-complex business environment to maximize warehouse operations, boost productivity, and guarantee customer satisfaction. Explore the world of software development services for WMS solutions to see how your warehouse procedures can be improved by the appropriate technology.

This in-depth manual goes into the development of WMS solutions, their essential elements and features, and the indisputable advantages of adopting this revolutionary technology. Discover how to select the ideal WMS for your particular company requirements, put it into practice with ease, and track its effectiveness to promote ongoing enhancements in your warehouse operations. With this information at your disposal, you’ll be well-positioned to make a calculated choice that will enhance your warehouse’s capabilities and help your company grow.

What is WMS Software – A Simple Definition

An advanced software platform called a Warehouse Management System (WMS) is used to automate and combine various warehouse processes. With its unmatched visibility and control over warehousing operations, it simplifies inventory management, warehouse organization, and order fulfillment for enterprises. Businesses can increase customer happiness and productivity by utilizing a WMS. A well-known logistics software development company can help you to develop a feature-rich WMS solution.

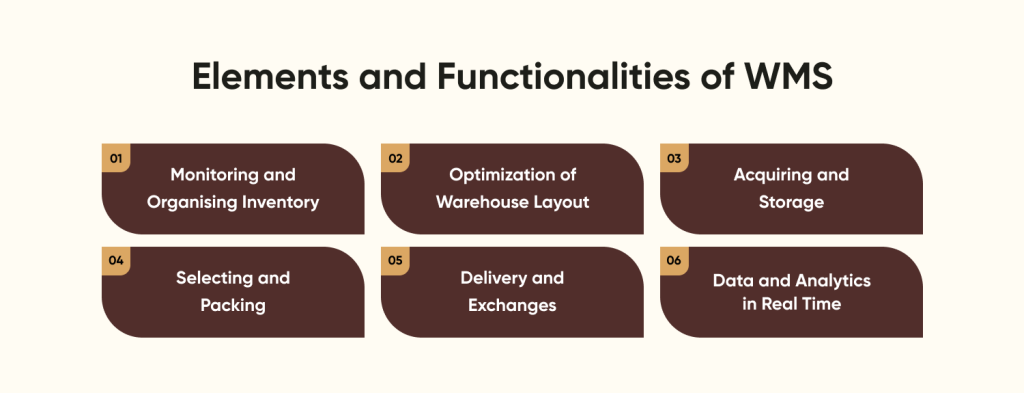

Elements and Functionalities of WMS

A modern WMS is a powerhouse of features and capabilities intended to boost productivity and streamline warehouse operations. Among the salient characteristics are:

1. Monitoring and Organising Inventory

With the sophisticated inventory tracking and management features that a WMS provides, you can keep an eye on your stock levels and manage them in real time. Your inventory records will always be accurate and current because of the system’s use of barcodes, RFID tags, and other tracking technologies. This enables you to cut carrying costs and prevent stockouts by making more informed decisions about stock replenishment.

2. Optimization of Warehouse Layout

A well-thought-out logistics app development for a warehouse is essential to attaining optimal operational effectiveness. A WMS helps you design the best possible layout by examining elements like product size, storage needs, and material flow patterns. The end product is a data-driven, strategic warehouse design that optimizes space usage and simplifies material handling procedures.

3. Acquiring and Storage

Maintaining correct inventory records and avoiding bottlenecks need efficient receiving and put-away procedures. By creating and allocating storage places for arriving products, confirming their accuracy, and instantly updating inventory data, a WMS automates these procedures. The technology makes receiving and put-away easier, which lowers the possibility of mistakes and guarantees the efficiency of your warehouse operations.

4. Selecting and Packing

By using cutting-edge algorithms to create optimal picking routes and automate packing processes, a WMS transforms the picking and packing process. This lowers the possibility of errors while simultaneously cutting down on the time and labor needed to fulfill orders. By using a WMS, you can make sure that your clients receive their orders precisely and quickly, which will boost their happiness and loyalty.

5. Delivery and Exchanges

By automating processes like carrier selection, label creation, and shipment tracking, a WMS makes shipping and returns easier to understand and more efficient. This lets you handle returns with efficiency, cut down on shipping costs, and expedite delivery timeframes. A WMS can assist you in preserving a competitive advantage in the market by streamlining your shipping and returns procedures.

6. Data and Analytics in Real Time

Encouraging continual development and making well-informed decisions require access to real-time data and analytics. With the abundance of data a WMS gives you on your workers, operations, and inventory, you can see patterns, find inefficiencies, and keep an eye on your warehouse’s performance. Equipped with this information, you may make calculated choices that advance your warehouse operations.

7. Integrating with Different Systems

ERP, TMS, and CRM are just a few examples of enterprise systems that a WMS should be able to interact with to ensure smooth data exchange and improved operational efficiency. By removing data silos and enabling better decision-making, this integration guarantees that every department in your company has access to accurate, current information. Moreover, new synergies can be unlocked through system integration.

Benefits of Warehouse Management System

The advantages of a warehouse management system, which include cost savings and increased production, should be taken into account by expanding companies. Let’s go over the list of advantages that WMS offers that will justify an investment for your company.

1. Enhanced Accuracy and Control over Inventory

By giving you real-time insight, tracking, and control over your stock levels, a WMS improves inventory management. Accurate inventory records are guaranteed by automated inventory updates and sophisticated tracking tools like RFID tags and barcodes, which also remove human error. Stockouts and overstocking can be eliminated with a WMS in place, which will eventually save carrying costs and improve customer satisfaction.

2. Optimized Use of Warehouse Space

Optimizing the usage of warehouse space is essential for streamlining processes and cutting expenses associated with overhead. With a WMS, you can precisely plan and oversee your warehouse layout, strategically allocating storage places through the use of sophisticated algorithms. You may store more products in the same footprint, require less material handling, and operate more efficiently overall by making the most use of available space.

3. Simplified Procedures for Order Fulfilment

A WMS optimizes and automates picking, packaging, and shipping tasks, revolutionizing your order fulfillment procedures. The technology reduces labor requirements and travel time by generating optimized picking routes through the use of sophisticated algorithms. Automated packing procedures also guarantee that orders are filled precisely and quickly. What was the outcome? quicker order processing, fewer mistakes, and happier clients.

5. Efficiency in Work and Cost Cutting

You may drastically cut labor expenses by automating tedious processes and optimizing staff deployment when you have a WMS in place. With the help of the system’s real-time data, you can spot inefficiencies and bottlenecks and use that information to inform your resource allocation and staffing decisions. The result is a staff that is leaner and more productive, which benefits the bottom line.

6. Better Satisfaction and Customer Service

Your capacity to provide outstanding customer service is directly impacted by a WMS’s ability to streamline your warehouse operations. Customer satisfaction is increased by accurate inventory records, effective order fulfillment, and quicker shipment times. In addition, the sophisticated analytics of the system enable you to anticipate and resolve prospective problems before they arise, guaranteeing your clients’ optimal experience.

7. Reporting and Compliance with Regulations

In a business setting that is becoming more and more regulated, a WMS can be your go-to tool for ensuring compliance and streamlining reporting. The system maintains thorough logs of your inventory and activities, making it simple for you to create precise reports. Through adherence to industry norms and guidelines, a WMS not only shields your company from fines but also enhances your standing in the marketplace.

Types of Warehouse Management System (WMS)

Since every organization is different and for the seamless warehouse management process, it is essential to select a system that meets their demands. The most popular kinds of WMSs among the several varieties are as follows:

Standalone Systems

A simple standalone solution would be appropriate for smaller warehouses or those that don’t want to add new technology to their supply chain operations. For example, more recent e-commerce companies are still refining their logistics and supply chain procedures.

A stand-alone system is economical, maintains inventory control, and oversees a warehouse. Unfortunately, because this technology needs extra software and equipment to operate the warehouse, a corporation cannot achieve much with it. As a result, companies that want to grow and need additional technology in the future may wish to invest in another robust system.

ERP Modules

Software for enterprise resource planning, or ERP, is ideal for growing companies looking to reduce labor costs, increase productivity, and automate processes. Robust reporting, several units of measure, many locations and currencies, email connectivity, limitless file size, and high transaction volume are just a few of the system’s many notable features. ERPs typically change as the business does. Examples include barcode scanning, lot tracking, landing cost monitoring, mobile picking, two-way communication with e-commerce websites, and CRM.

Sadly, the advantages of an ERP system don’t become clear until much later onâthis is an expensive process. Another drawback is that staff education and training in proper system usage is crucial to the efficacy of an ERP installation.

Employing staff resources is crucial for organizations when choosing which ERP system to purchase. The heads of operations, finance, and IT, as well as possibly sales, marketing, and HR, may be involved in this intricate process. Businesses using labor-intensive methods, such as spreadsheets and mountains of paper documents, might require the assistance of an integration professional to assist with the protracted data migration process. Employee resistance is possible when the leadership team is against these innovative methods and tools.

Modules for the Supply Chain

The art of supply chain management involves delivering the right goods at the right cost, location, and time. It controls the flow of products and services, including finished items, work-in-process inventories, and raw materials.

Supply chain modules (SCM) manage the entire supply chain, as opposed to systems that merely handle storage. Software for supply chains helps with several functions, including risk assessment and managing supplier relationships, customers, transportation, material handling, and inventory control. Additionally, it automates stock management, material purchases, and product cycles. One SCM platform may house all of your fleet, inventory, and warehouse management solutions. Larger businesses and third-party logistics providers typically favor supply chain systems (3PLs).

Cloud-based Systems

A SaaS-based warehouse management system is referred to as a cloud-based WMS. Because the entire interface is web-based, users may view it from any device connected to the internet, no matter where they are.

The company does not require any hardware on-site because program data is executed and stored on distant servers. The license fee is paid monthly by the client; no servers or equipment need to be installed or maintained.

Cloud-based warehouse platforms offer numerous advantages, such as seamless integration and user-friendliness. Because they are hosted on servers and systems outside of your company, they are far simpler to set up and maintain technically. Its ability to unite all aspects of a business into a single platform simplifies and eases users’ work, which is another noteworthy benefit.

Examples of Warehouse Management System

It’s important to weigh the advantages of the best current solutions and their essential warehouse management system features before determining whether you need to build your own WMS. Here are some of the warehouse management system examples:

Microsoft Dynamics 365

The warehouse management procedures of order selection, inventory software development, delivery and dispatch, and product loading and unloading may all be optimized with Microsoft Dynamics 365. provides complete supply chain management application integration with various warehouse types and apps. In addition, the device has sophisticated counting features and can print labels. Its numerous warehouse management system features and availability as a mobile application are advantages for any approach.

Extended Warehouse Management for SAP

With the help of this program, you may oversee extensive warehouse operations. You may integrate the supply chain with your warehousing and distribution procedures and select between local or cloud implementation.

Conclusion

Putting in place a strong Warehouse Management System (WMS) is no longer an optional luxury in the quickly changing corporate environment. This in-depth 2024 guide demonstrates how a WMS can revolutionize your business processes and boost supply chain profitability, accuracy, and efficiency.

The choice of a WMS should be by your particular business demands and future growth plans, regardless of whether you choose supply chain modules, cloud-based systems, standalone systems, or ERP modules. See notable gains in inventory control, labor cost reduction, order process simplification, warehouse area optimization, and customer satisfaction by implementing a WMS.

WMS technology is still evolving, so it’s essential to take advantage of innovations like AI, machine learning, and the Internet of Things. This blog acts as your road map, providing insightful advice and industry best practices to help you navigate the world of WMS systems. Outsource app development for your warehouse management system to streamline your operations and embrace the digital warehousing of the future. Do you feel prepared to take the risk?

Frequently Asked Questions

1. Why is Warehouse Management Software Important?

WMSs are essential to supply chain management because they control the order fulfillment process from the point of receiving raw materials to the point of exporting finished items. For example, if raw materials are not received correctly or if parts are misplaced at a warehouse, the supply chain may slow down or stop altogether.

2. Is Warehouse Management Software Suitable for Small Businesses?

Small firms might benefit from a WMS by receiving goods and effectively processing them into the system. Additionally, a WMS is a useful putaway management tool since it guarantees that items are arranged in the warehouse in the best possible ways.

3. Can Warehouse Management Software Integrate with Other Business Systems?

To offer complete supply chain visibility and smooth data flow, a WMS connects with other systems. It guarantees current and accurate data on orders, shipping, and inventory. A warehouse management system minimizes delays, lowers errors, and improves operational efficiency.

4. Which Software Is Best for Warehouse Management?

There are multiple software for the best warehouse management:

- ShipHero.

- Cin7 Core.

- Odoo Inventory.

- Blue Yonder Warehouse Management.

- Increff WMS.

- Softeon Warehouse Management System.

- ShipBob.

- Fishbowl Inventory.

5. What Are the Common Challenges in Implementing Warehouse Management Software?

Issues with warehouse management, such as entering data by hand, handling merchandise too much, and having many employees use the same ticket, can be expensive and time-consuming.

- Incorrect inventory

- Efficiency of the warehouse

- Redundant procedures

- Poor order processing

- Inaccurate inventory

- Selecting optimisation

- Labour expenses

- Insufficient room Manual procedures